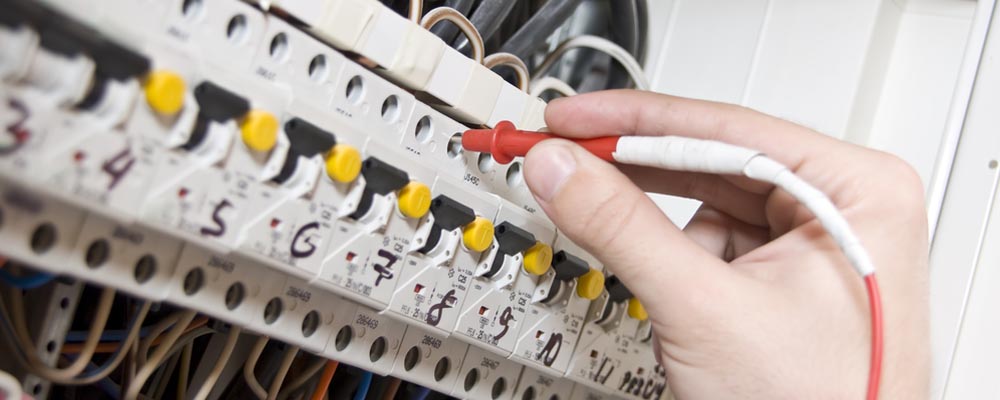

New GS38 Regulations have come into force with regards to Dead Test Procedure

In Short

- Test Leads should be in Good Condition and fused, a proving block is required in order to prove the test leads prior and after dead test.

- A multi meter will NOT be suitable for proving dead or safe isolation procedure.

- A Non-contact voltage indicator (Voltage Stick) will NOT be suitable for DEAD test procedure.

Powercor will be issuing all staff with Dead Test Training and New Test Leads

The full guidance is below

Health & Safety Executive GS38 guidance note is aimed at people (including electricians, electrical contractors, test supervisors, technicians, managers, tradespeople and/or appliance retailers/repairers etc) who use electrical test equipment on low voltage electrical systems and equipment. The document provides advice and guidance on how to work safely and ensure the right equipment is used and maintained properly – see our maintenance and compliance page. In June 2015, the fourth edition of Guidance Note GS38 was published. While it has fundamentally remained the same as the previous version, there are some key additions that could affect the way you test, or the equipment you are using. We look at the key changes in the fourth edition, the full version of which can be downloaded at the end of this article.

General changes

The guidance note has been amended to reflect the wide range of people who work on electrical systems, particularly those where electrical testing is not a primary activity such as gas installers and alarm installers.

A footnote has been added to clarify that live working is defined as any testing or fault finding on live systems.

A new section has been added entitled “Test Equipment”, this was previously entitled “Design Safety Requirements”. This section has some in-depth points regarding correct equipment selection.

Other changes include the use of proving units, non-contact voltage detectors and installation category ratings.

Updates regarding the causes of accidents

This section has been expanded on to include additional issues that have been raised since the previous publication:

- Inadequate insulation of connectors

- Removal of the manufacturer’s insulation on test leads and probes

- A multimeter being set to the wrong function, eg set on a current range when measuring voltage

- Using inadequately maintained test leads with visible damage, cracking, fraying or cut insulation or where normally insulated metal parts are exposed (these should be discarded or replaced)

- Using test leads that have become contaminated with conductive materials

- Severing of a test lead by a shearing effect

- Exceeding the CAT rating of the test equipment (including test leads, probes or clips), eg using CAT II rated equipment on a CAT III installation.

There are several points highlighted here that should be considered closely when it comes to test equipment selection.

GS38 & Safe Isolation

The fourth edition of GS38 has included some important points which apply particularly to safe isolation procedures, both with the test equipment used and the way the process should be carried out.

Firstly the Guidance Note has been amended to reflect relevant changes to the standard for two pole voltage indicators, BS EN 61243-3. This standard, which came into full effect in May 2013, is the standard that all new two pole voltage indicators should comply with. When it comes to buying new voltage detectors, you can be sure compliance with GS38 if the unit you are buying complies to BS EN 61243-3.

An important point raised in the causes of accidents is the use of multimeters. When it comes to proving dead this has always been advised against by Electrical Safety First (previously the Electrical Safety Council). Setting the multimeter to the wrong voltage range will lead to a false reading, but having it set to measure current or resistance can result in excessive current being drawn through the test probes, leads and multimeter.

Under the “Safe Systems of Work” section, a new paragraph has been added covering the use of proving units. This section states:

“Any device used to prove dead may fail to indicate danger (eg a faulty lamp not indicating a live circuit). Such devices should be proved before and after use. This should be done preferably on a voltage proving unit (some devices have built-in proving units) or otherwise on a known live source of similar voltage to the circuit under test (providing precautions are taken to prevent danger arising).”

A final note in regard to safe isolation comes under the newly added “Test Equipment” section. This has a new paragraph added regarding the use of non-contact detectors, or volt sticks:

“Single-pole or non-contact live-circuit detectors sometimes referred to as ‘voltage sticks’ should only be used for identifying live equipment, not for proving that it is dead. There are particular requirements for the use of non-contact devices in coalmines. Only devices which make contact with the conductor (ie not proximity devices) should be used for proving dead. However, non-contact or proximity devices can be useful in indicating if something is live, eg when attempting to remove a single cable installed in trunking containing many single cables.”

GS38 & Installation Categories

In the previous edition, measurement categories were never specifically mentioned. This has changed in the fourth edition, emphasising the importance of using test leads and test equipment that is suitable for the category of the installation.

This is an important safety issue as using equipment that is not correctly rated for the installation category can and has resulted in serious injury and death. It’s also important to understand that test instruments and test leads are to be treated as separate entities. Using CAT II rated test leads connected to a CAT III rated instrument would not be suitable for testing a CAT III installation. This approach would derate the measuring equipment to the lower rating.

These regular references to CAT safety ratings in the fourth edition of GS38 highlight the importance of ensuring that you have the right equipment and test leads for the job. Clarification of the different installation categories (BS EN61010-1 CAT ratings) is included in the guidance note as a reference and a visual guide is available to download at the end of this article.

Specific requirements for test leads

In line with changes made to the standards that cover the manufacture of test leads, there are some specific requirements that leads should comply with added in the fourth edition:

- Conform to the requirements of BS EN 61010-031 or in the case of a 2 pole voltage detector to BS EN 61243-3

- Be marked with the rated installation category – CAT II, III or IV

- Be marked with the manufacturer’s name or identifying mark;

Test leads can often be overlooked when it comes to testing. If your leads break during testing it can be easy to swap them for another set from a multimeter or clamp meter. However, if those leads are not rated to the same category as your installation, you could be putting yourself at risk.

A final change regarding test leads relates to the use of fused leads. For multimeters, fused leads should have a high-breaking capacity fuse (hbc or hrc) with a current rating that usually should not exceed 500mA. For loop impedance, RCD or multifunction testers, the fuse will typically be 10A.

If you are unsure as to what test leads you need to use, speak to the Technical Team on 01923 442244.

Precautions before testing

This section has been expanded upon to recognise additional test processes covered by the guidance note. A newly added paragraph touches on the importance or carrying out risk assessments, putting into place relevant safety measures and the use of appropriate PPE.

Throughout this section, revisions have been made to include the need for ongoing risk assessments to ensure safety is maintained as well as re-emphasis of the need for selecting the right CAT safety rating for the installation under test.

Examination of equipment

The changes here are mainly with the wording, however this section does highlight the need to maintain regular checks of test equipment and that these should be carried out by a competent person.

Two key points have been added to the examples of common problems to look for:

- Damaged spring-loaded retractable covers to the tips of probes

- Failing to verify correct function of illumination (eg indicator / lamp / neon)

The use of a suitable proving unit will help in checking for voltage indicator and test lamp faults

Will I need to replace my old test equipment & leads?

Whenever there are changes made to legislation and best practice, questions are often raised regarding existing equipment and whether it can still be used. The fourth edition of GS38 makes two important points regarding the purchase of new equipment and the use of older equipment.

- As a general rule, GS38 states that any equipment or test leads that conform to BS EN 61010 or BS EN 61243-3 will meet the requirements and be compliant, provided you have taken into consideration the installation category.

- For existing leads and equipment predating these standards, or manufactured to a different standard, GS38 states they must be maintained to prevent danger and should comply with the guidance probes and clips in paragraph 9 (download the full guidance note below

Provided your existing equipment or leads meet either of the above there should be no need to replace anything until they need it.

If you find you have leads or test equipment that no longer meet these requirements, or have been damaged, it would be advisable to replace them to ensure your ongoing safety.

Download the full HSE Guidance Here

We will be issuing all our staff with Dead Test Training and New Test Leads